Do you want to know what it would be like to have designs created with increased detail and accuracy than you ever thought was possible?

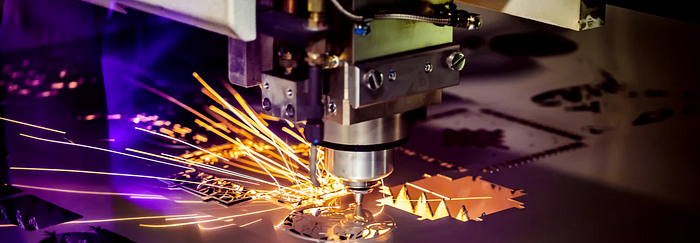

That is the sparkling truth about CNC machining services. Such techniques rely on computerized tools in order to make parts fit precisely into the particular design that a product demands. The service is organised in a way that the technology and traditional approach in the cutting, drilling, and milling processes are integrated for quality results.

Learn about CNC machining solutions to create your projects with the exquisite detail that is not amenable to any change.

Finding Quality Nearby: Custom CNC Machining Near Me

Is there any company which provide “custom CNC machining near me”? It becomes a daunting task sometimes to search the appropriate company. Nonetheless, local providers represent an impressive convenience and individual attention. Whether you are looking for prototype a new design or require production ready parts these services offer customized solutions within your own country. When seeking for customized solutions using CNC machining near you, current high-quality and quick turnaround time, reasonable prices, and process innovations that are tailored to suit the requirements of every unique firm. Distance is not the answer; go to custom cnc machining near me for quality and assurance of close by vendors.

Perfectly Engineered: Custom Metal Parts

Every innovation has quality as its basis, as do the innovations of Niki Lauda and Red Bull. Metals are a key component in an amazingly large number of industries ranging from aviation to retail ones. These are manufactured to special requirements to guarantee correctness thus helping machinery work effectively. Purchasing custom metal parts provides a company with an ability to create, higher reliability, highest quality and the best performance. For gears, brackets or even designing, custom metal parts are the way to go whether you are seeking an element of durability or everyday dependability.

Customization for Unique Challenges

- Solutions that correspond to certain conditions prevailing within an organization.

- Products for ultra high temperature and severely corrosive services.

- Products for aerospace, robotic and related industries that require lightweight materials.

- Improved wearing properties for bearing heavily loaded machineries.

- In some element designs that are delicate and complicated, accuracy is extremely important.

Precision Cutting Edge: Wire EDM Services

When it comes to complex and delicate manufacturing, wire EDM services are especially notable for coming through well on complexity of any kind of design. Wire EDM is an electrical process that uses sparks to remove material from the metal in question to an incredibly small degree. This makes wire EDM services suitable for components that require a high level of accuracy in terms of tolerance, and / or sensitive geometric patterns. These services are very accurate whether dealing with aerospace parts or medical tools. Wire EDM services should be availed to develop designs that bring the unthinkable to reality and beyond.

Simplifying Customization: Order Custom Metal Parts

Do you require metal components and you want them to be as precise as possible? The need to procured tailored metal components is real once again. This has made it easier for you to describe the materials, size and even the finish to meet you needs. In every aspect, from developing a prototype to the eventual production of metal parts, ordering can guarantee that everything is built to specification. Furthermore, it has become far easier to order custom metal parts online with just a few clicks, which adds ease and accuracy to your reach.

High-Tech Craftsmanship: CNC Machining Services

CNC machining services are the best machining services for modern manufacturing. These services feature the use of superior technology in development of parts with unmatched precision and regularity. From aerospace engineering to robotics, and from medical devices to automotive, CNC machining services are ubiquitous. They are more efficient and consistent than others and guarantee projects to be delivered without compromising on quality. Experience and productive manufacturing by choosing the professional CNC machining service now.

Technological Advancements

- Using CAD/CAM integrated solutions for realization of coordinated design for manufacturing processes.

- Application of multi-axis machines to cut compound arrays of geometrics and inclined structures.

- Automation and robotics with a view of reducing on human intervention to minimize on errors.

- Some of the benefits of real time monitoring and analysis of measurable data are improving quality control.

- Most technological innovations in tooling are focused on the quality of the structural material in order to obtain better performance and longer life cycles.

Tailored Excellence: Custom Machined Parts

With today’s throwaway culture a like a custom machined part is a welcome refreshing return to uniqueness. These components are made with high level of accuracy to suit specific requirements for purpose in order to form a perfect fit for your application. From fashion to business, and from technology to automotive, custom machined parts represent exceptional and innovative production. Trust us to make your dream come true providing you professional custom machined parts for your dream project.

Crafted for Your Needs: Custom CNC Parts

Every project is unique, and this is the reason why we need customized cnc parts. These parts are manufactured with accuracy and made to meet particular needs to guarantee that they would not cause any hitch in your systems. Whether you are the innovation manager of a start-up robotics company or the CEO of a healthcare technology company, it all begins with custom CNC components. Use custom CNC parts to take advantage of great flexibility and high accuracy to provide power to your great idea.

Innovate with Precision: 3D Printing Metal Service

Welcome to the new era of production through 3D printing metal service. This branding-new technology adds the dexterity to the hardness of metal and makes metal structures in layers. Maximum flexibility — with 3D printing metal service, rapid prototyping, and complicated styles are only a slice of the pie. This has the effect of guaranteeing durability across aerospace, automobiles and consumer products while not restricting creativity in the process. Discover how endless possibilities with 3D printed metal service can revolutionize the manufacturing industry.

Customization and Design Freedom

- Freedom from restrictions of most geometries while you can make them as intricate and as complex as you wish.

- The choice and configuration of components can be adapted for a specific requirement for different markets.

- Facilitate quick changes so that product form is continuously improved with the right form and function.

- Enable easy incorporation of several functions into a single part.

- Promote creative and innovation designs of prototype and production.

Engineering Brilliance: CNC Custom Machining

CNC custom machining gives you the ability to convert concept into accurately designed and manufactured product. This process caters for your precise requirements and provides parts in excess of the required quality. This means that if it is a one-of-a-kind prototype or simply an industrial part that cannot be replicated by other means, CNC custom machining guarantees making parts right. Engage professionals to unleash the capability of CNC custom machining on your business and improve manufacturing.

Building Innovation: Custom Components

As they say: Where there is nothing but the basics, there must be great beginning too. Custom components are versatile and accurate mainly used in different fields or areas. These special bearings further enhance performance, reliability and adaptability into your Systems. In the case of this portfolio, it is noted that innovation begins at a molecular level and, specifically, with the creation of customized components. Learn how custom components are dependable and can be integrated into your next project.

Applications of custom components:

- Aerospace: Optical communication, avionic systems, missile control systems, space stations, spacecrafts, satellite communications equipment etc.

- Automotive: Components for engines, automatic transmission, clutches, gearchange systems and other safety related parts.

- Medical Devices: Ear Implants, surgical instruments, diagnostic apparatus, computer peripheral equipment's.

- Electronics: Consumer electronic housings, connectors, and printed circuit boards made from components suited to meet specific user requirements.

- Energy: Components for turbines, generators, and energy storage systems were discovered to be best served by customization.

- Defense: Spares parts for defense equipment, unmanned aerial vehicles and ground vehicles. Robotics: made-to-order robotic actuators, sensors and structural parts.

Strength in Design: Metal 3D Printing

Take advantage of the latest breakthrough in technology; metal 3D printing for your manufacturing needs. It forms precise and light parts without the use of many invitations, enhancing component strength. In prototype and direct production, metal 3D printing gives creativity and efficiency to upgrade a center. Aerospace, defense and robotics industries are among those that deploy metal 3D printing because it endless and performs exceptionally. Learn how applications with metal 3D printing can revolutionize your production process and generate ideas.

Conclusion: Unlock Your Manufacturing Potential

From cnc machining services to metal 3D printing the latter envisioned possibilities these tools enable companies to create with accuracy and speed. When you encourage and invest in specialized services such as custom CNC parts or wire EDM services, it means every project is optimized throughput anchored on the company’s core strengths.

Are you in the line of creating a new product?

Which of these great services will each of you start off with, on his or her transformation journey?